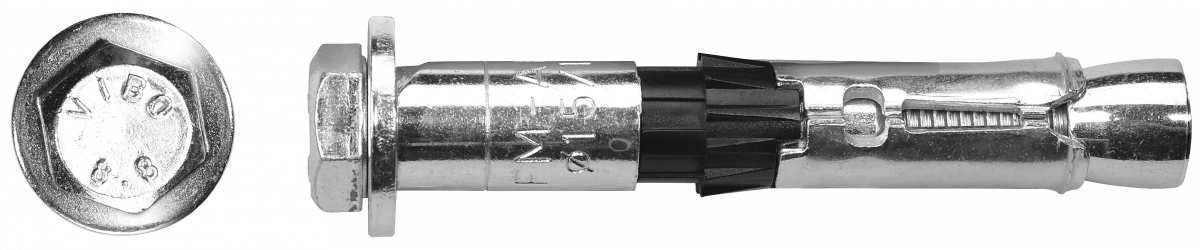

R-SPL-II-L SafetyPlus II - Loose Bolt

High performance mechanical anchor - loose bolt option

Features and benefits

- Mechanical anchor for highest tension and shear loads

- Seismic category C2 for structural applications. Seismic category C1 for non-structural use in areas with low seismic risk.

- For usage with required fire resistance

- ETA Option 1 for cracked and non-cracked concrete.

- Antirotation brush to prevent rotation during installation.

- Anchor's construction allows easy through-installation (drilling and installation through fixed material)

- Three types of tips (nut, flat or tapered bolt) allow simple fitment for installed element

- 8.8 grade steel material of anchor provides high durability

Product information

Size |

Product Code |

Anchor |

Fixture |

|||

Thread size |

External diameter |

Length |

Max. thickness |

Hole diameter |

||

d |

dnom |

L |

tfix |

df |

||

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

||

M6 |

R-SPL-II-06080/20L |

6 |

10 |

80 |

20 |

12 |

R-SPL-II-06110/50L |

6 |

10 |

110 |

50 |

12 |

|

M8 |

R-SPL-II-08080/10L |

8 |

12 |

80 |

10 |

14 |

R-SPL-II-08090/20L |

8 |

12 |

90 |

20 |

14 |

|

R-SPL-II-08120/50L |

8 |

12 |

120 |

50 |

14 |

|

M10 |

R-SPL-II-10090/10L |

10 |

15 |

90 |

10 |

17 |

R-SPL-II-10100/20L |

10 |

15 |

100 |

20 |

17 |

|

R-SPL-II-10130/50L |

10 |

15 |

130 |

50 |

17 |

|

R-SPL-II-10180100L |

10 |

15 |

180 |

100 |

17 |

|

M12 |

R-SPL-II-12110/10L |

12 |

18 |

110 |

10 |

20 |

R-SPL-II-12125/25L |

12 |

18 |

125 |

25 |

20 |

|

R-SPL-II-12150/50L |

12 |

18 |

150 |

50 |

20 |

|

R-SPL-II-12200100L |

12 |

18 |

200 |

100 |

20 |

|

M16 |

R-SPL-II-16125/10L |

16 |

24 |

125 |

10 |

26 |

R-SPL-II-16140/25L |

16 |

24 |

140 |

25 |

26 |

|

R-SPL-II-16165/50L |

16 |

24 |

165 |

50 |

26 |

|

R-SPL-II-16215100L |

16 |

24 |

215 |

100 |

26 |

|

Base material

-

Cracked concrete C20/25-C50/60

-

Non-cracked concrete C20/25-C50/60

-

Unreinforced concrete

-

Reinforced concrete

For use also with

-

Natural Stone (after site testing)

Applications

- Structural steel

- Masonry support

- Cladding restraints

- Road Signs

- Heavy machinery

- Racking systems

- Industrial doors

- Safety barriers

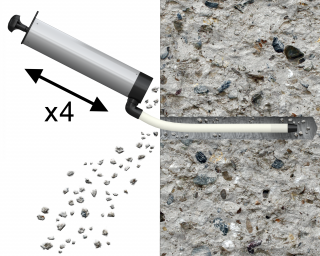

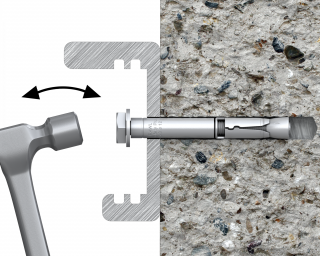

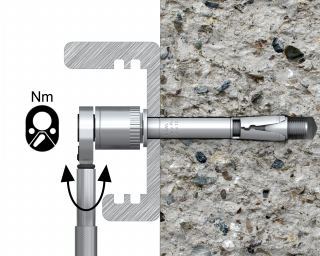

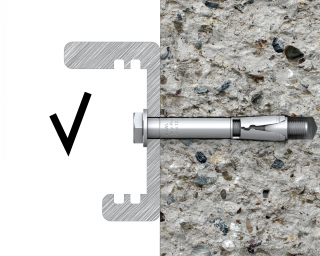

Installation guide

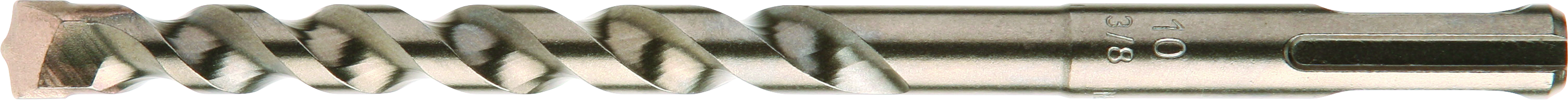

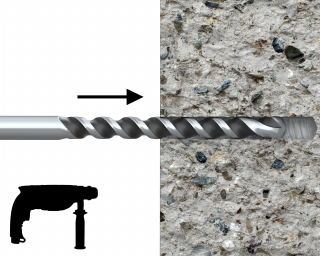

- Drill a hole of required diameter and depth

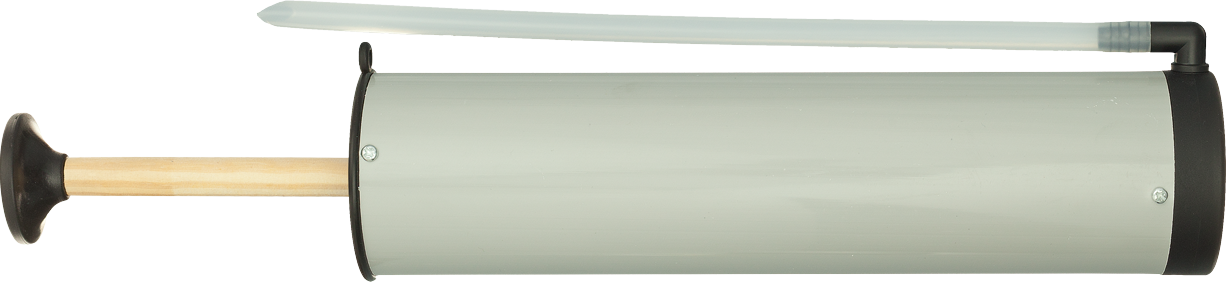

- Clear the hole of drilling dust and debris (using blowpump or equivalent method)

- Insert anchor through fixture into hole and tap until required installation depth is achieved

- Tighten to the recommended torque

Installation data

Size |

M6 |

M8 |

M10 |

M12 |

M16 |

||

Thread diameter |

d |

[mm] |

6 |

8 |

10 |

12 |

16 |

Hole diameter in substrate |

d0 |

[mm] |

10 |

12 |

15 |

18 |

24 |

Hole diameter in fixture |

df |

[mm] |

12 |

14 |

17 |

20 |

26 |

Installation torque |

Tinst |

[Nm] |

10 |

20 |

45 |

80 |

150 |

Wrench size |

Sw |

[mm] |

10 |

13 |

17 |

19 |

24 |

Min. hole depth in substrate |

h0 |

[mm] |

75 |

85 |

95 |

115 |

130 |

Min. installation depth |

hnom |

[mm] |

60 |

70 |

80 |

100 |

115 |

Min. substrate thickness |

hmin |

[mm] |

100 |

120 |

140 |

180 |

200 |

Min. spacing |

smin |

[mm] |

50 |

60 |

70 |

80 |

100 |

Min. edge distance |

cmin |

[mm] |

50 |

60 |

70 |

80 |

100 |