R-RB Rawlbolt® Shield

World's most popular all-purpose expanding shield anchor

Features and benefits

- Product recommended for applications requiring fire resistance

- Three-pieces expanding sleeve of maximum expansion provides optimal load and safety of use in any substrate

- Designed & manufactured for maximum performance

Product information

Size |

Product Code |

Anchor |

Fixture |

||

Diameter |

External diameter |

Length |

Hole diameter |

||

d |

dnom |

L |

df |

||

[mm] |

[mm] |

[mm] |

[mm] |

||

M6 |

R-RB-M06W |

6 |

12 |

45 |

6.5 |

M8 |

R-RB-M08W |

8 |

14 |

50 |

9 |

M10 |

R-RB-M10W |

10 |

16 |

60 |

11 |

M12 |

R-RB-M12W |

12 |

20 |

75 |

13 |

M16 |

R-RB-M16W |

16 |

25 |

115 |

17 |

M20 |

R-RB-M20W |

20 |

32 |

130 |

22 |

M24 |

R-RB-M24W |

24 |

38 |

150 |

26 |

For use also with

-

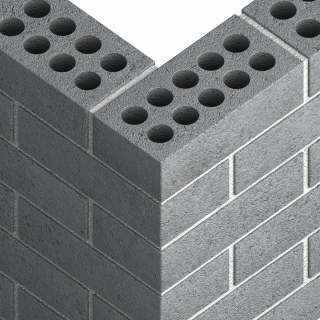

Cracked concrete C20/25-C50/60

-

Non-cracked concrete C20/25-C50/60

-

Unreinforced concrete

-

Reinforced concrete

-

Solid clay brick ≥ 20MPa

-

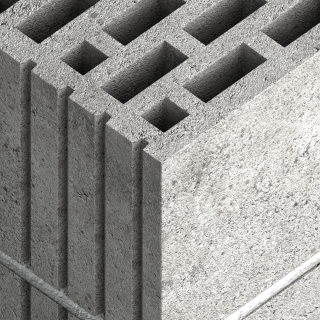

Hollow Lightweight Concrete Block LAC 5 ≥ 5MPa

-

Hollow Sand-lime Brick ≥ 15MPa

-

Concrete hollow floor block (eg. Teriva)

-

Hollow-core Slab C20/25

-

Hollow-core Slab C30/37-C50/60

-

Natural Stone (after site testing)

Applications

- Roller shutter doors

- Fire doors

- Wall plates

- Security grills

- Signs

- Manufacturing and installation of fencing

- Heavy machinery

- Pipework/duct work support

- Supporting guy ropes, stays and cables

- Supporting ladder restraints

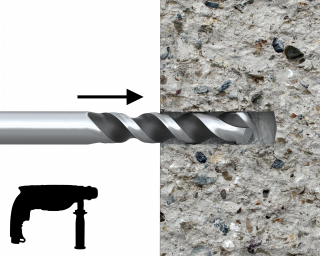

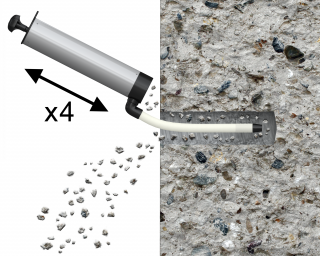

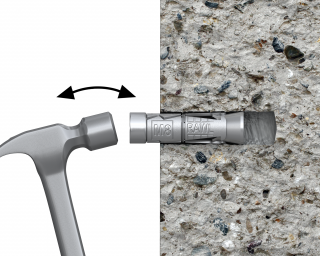

Installation guide

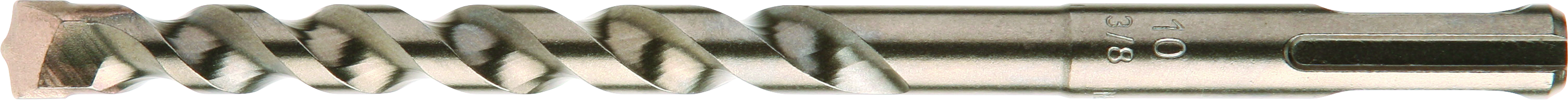

- Drill a hole of required diameter and depth. Note: When fixing into brickwork, mortar joints should be avoided

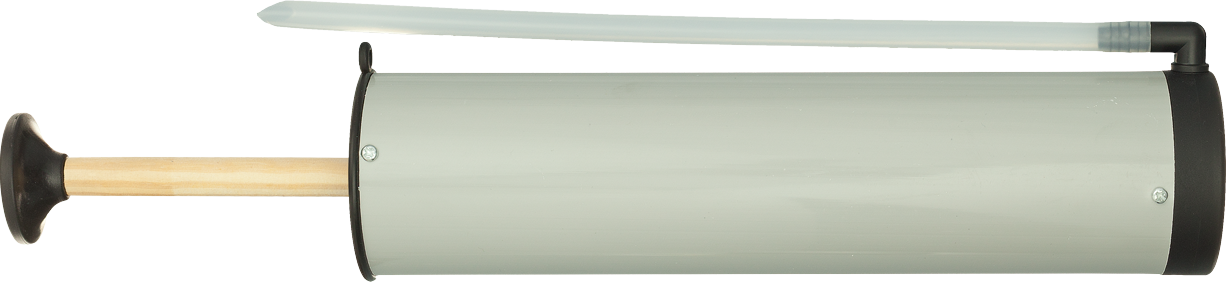

- Remove debris and thoroughly clean hole with brush and pum

- Tap home with hammer until flush with surface

Installation data

Size |

M6 |

M8 |

M10 |

M12 |

M16 |

M20 |

M24 |

||

Thread diameter |

d |

[mm] |

6 |

8 |

10 |

12 |

16 |

20 |

24 |

Hole diameter in substrate |

d0 |

[mm] |

12 |

14 |

16 |

20 |

25 |

32 |

38 |

Installation torque |

Tinst |

[Nm] |

6.5 |

15 |

27 |

50 |

120 |

230 |

400 |

Min. hole depth in substrate |

h0 |

[mm] |

50 |

55 |

65 |

85 |

125 |

140 |

160 |

Min. installation depth |

hnom |

[mm] |

45 |

50 |

60 |

80 |

120 |

135 |

155 |

Min. substrate thickness |

hmin |

[mm] |

100 |

100 |

100 |

100 |

142.5 |

172.5 |

240 |

Min. spacing |

smin |

[mm] |

35 |

40 |

50 |

60 |

95 |

115 |

210 |

Min. edge distance |

cmin |

[mm] |

53 |

60 |

75 |

90 |

143 |

173 |

188 |