R-OTR-63/70 Zinc flake self-drilling screws to composite panels to concrete and timber

Special double thread type HiLo with cuts for drilling in wood and for embedding in concrete after pre-drilling.

Features and benefits

- Hardened screw's thread surface. High quality anti-corrosion coating guarantees resistance of 15 Kesternich cycles.

- Shape of the tip facilitating correct turning and allowing penetration in wood and concrete.

- The shape and type of screw's thread is designed specifically for connecting to concrete and wood. The drill point is designed to provide a fast and hassle-free installation. Sharp point of the drill prevents movement of the surface of the fixture.

- Special zinc flake coating for increased corrosion resistance

- Self vulcanizing EPDM washer. Temperature and UV resistant. The special shape of the washer ensures proper seating of the sealing material on the outer cladding material fixture which guarantees a proper seal.

- Two type of thread : first for fixing in the ground, second with a larger pitch under the head protects against indentation of the outer cladding of the board and helps in sealing the connection

Product information

Size |

Product Code |

Screw |

Washer size |

Drill diameter |

Fixture |

||||

Diameter |

Length |

Head size |

[English]: Max grubość elementu mocowanego z podkładką - drewno |

[English]: Max grubość elementu mocowanego z podkładką - beton |

|||||

d |

d1 |

l |

S |

- |

Ø |

tfix |

tfix |

||

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

- |

- |

||

Ø6.3/7.0 |

R-OTR-63/70095A19 |

6.3 |

7 |

95 |

8 |

19 |

5 |

60 |

65 |

R-OTR-63/70115A19 |

6.3 |

7 |

115 |

8 |

19 |

5 |

80 |

85 |

|

R-OTR-63/70135A19 |

6.3 |

7 |

135 |

8 |

19 |

5 |

100 |

105 |

|

R-OTR-63/70155A19 |

6.3 |

7 |

155 |

8 |

19 |

5 |

120 |

125 |

|

R-OTR-63/70185A19 |

6.3 |

7 |

185 |

8 |

19 |

5 |

150 |

155 |

|

R-OTR-63/70205A19 |

6.3 |

7 |

205 |

8 |

19 |

5 |

170 |

175 |

|

R-OTR-63/70235A19 |

6.3 |

7 |

235 |

8 |

19 |

5 |

200 |

205 |

|

R-OTR-63/70255A19 |

6.3 |

7 |

255 |

8 |

19 |

5 |

220 |

225 |

|

Base material

-

Wood

-

Timber

-

Concrete

Applications

- Composite panels to thick wall hot rolled steel sections

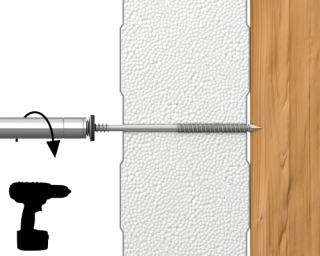

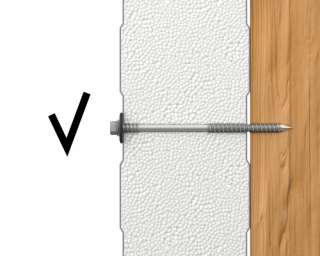

Installation guide

- Screw must be installed at 90 degrees to substrate.

- Magnetic driver must be used.

- Lowest torque setting on impact screwdriver to start.

- Reduce speed when the washer starts to deform.

- Use a cordless Impact screwdriver. Note: Never use a power drill.

- For installation please use screwdriver of load capacity 1600 - 2000 rpm with regulated trogue.

Installation data

Size |

Ø6.3/7.0 |

Ø6.3/7.0 |

||

Wrench size |

Sw |

[mm] |

8 |

8 |

Hole diameter in substrate |

d0 |

[mm] |

- |

5 |

Min. hole depth in substrate |

h0 |

[mm] |

- |

35 |

Min. installation depth |

hnom |

[mm] |

30 |

25 |

Min. substrate thickness |

hmin |

[mm] |

30 |

100 |

Min. spacing |

smin |

[mm] |

30 |

40 |

Min. edge distance |

cmin |

[mm] |

25 |

40 |

Substrate |

Timber, grade C24 |

Concrete C20/25 - C50/60 |

||

Screw diameter |

d |

[mm] |

6.3/7.0 |

6.3/7.0 |