R-ITS-Z Internally Threaded Sockets

High load-bearing capacity

Features and benefits

- Allows removal of bolt to leave a re-usable socket in place

- High load-bearing capacity

- Close edge and spacing distances

- Expansion free functioning

- Available in zinc plated and stainless steel versions

Product information

Size |

Product Code |

Anchor |

Fixture |

Diameter |

|||

Socket diameter |

Length |

Internal thread length |

Max. thickness tfix for: |

Hole diameter |

|||

d |

L |

lg |

hnom,std |

df |

d1 |

||

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

||

M6 |

R-ITS-Z-06075 |

10 |

75 |

24 |

- |

7 |

- |

M8 |

R-ITS-Z-08075 |

12 |

75 |

25 |

- |

9 |

- |

R-ITS-Z-08090 |

12 |

90 |

25 |

- |

9 |

- |

|

M10 |

R-ITS-Z-10075 |

16 |

75 |

30 |

- |

12 |

- |

R-ITS-Z-10100 |

16 |

100 |

30 |

- |

12 |

- |

|

M12 |

R-ITS-Z-12100 |

16 |

100 |

35 |

- |

14 |

- |

M16 |

R-ITS-Z-16125 |

24 |

125 |

50 |

- |

18 |

- |

Base material

-

Non-cracked concrete C20/25-C50/60

Applications

- For fastening bolts

- Safety barriers

- Temporary works/formworks support systems

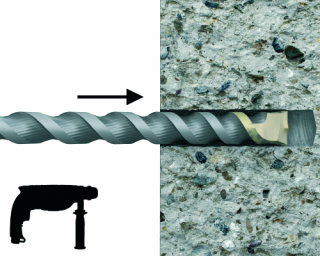

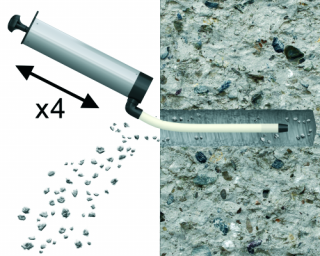

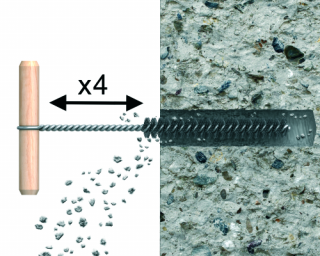

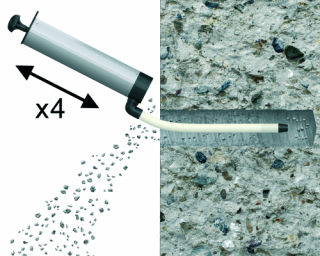

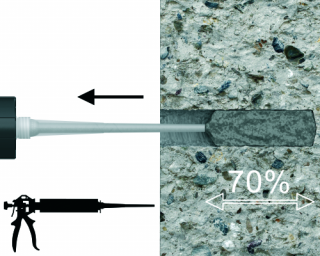

Installation guide

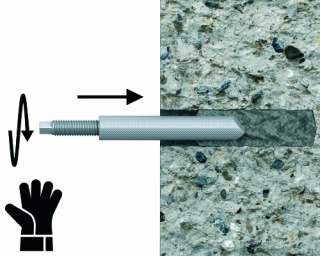

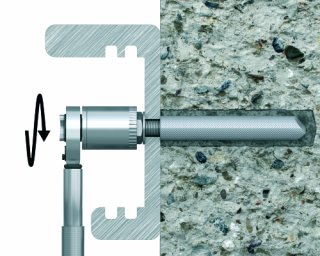

- After injecting resin, immediately insert the socket anchor, slowly and with a slight twisting motion until flush with surface

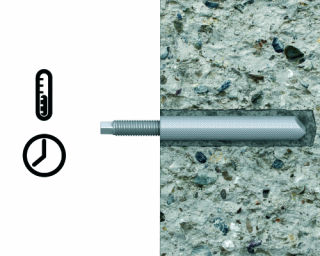

- Remove excess resin, then leave anchorage undisturbed until curing time has elapsed

- Fill hole with the required resin to the recommended fill level. (Follow the relevant instructions for the resin product)

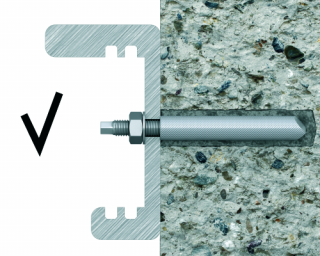

- Attach fixture and tighten the nut to the required torque.