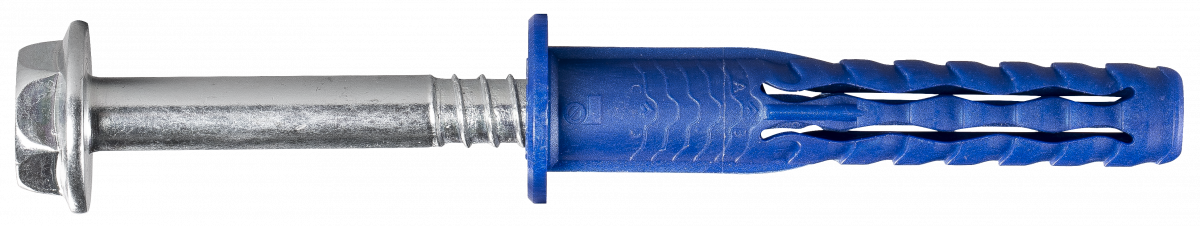

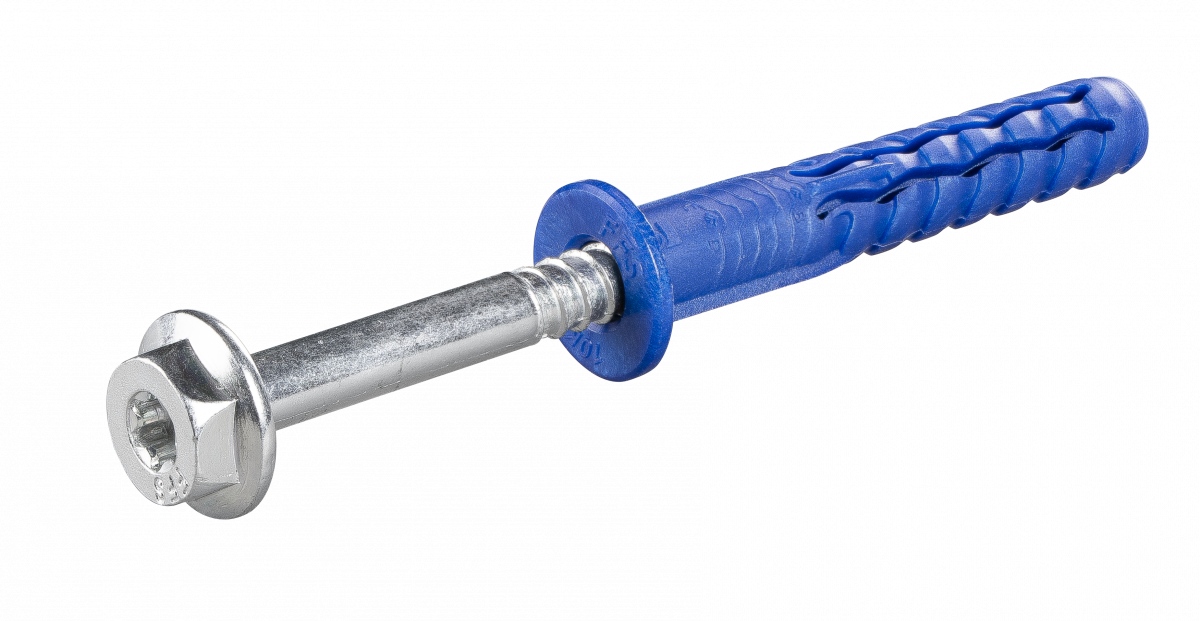

R-FFS-K Frame fixing with the shortest anchoring zone and collar hex head - zinc plated

Universal frame fixing with collar and hex head screw for many applications

Features and benefits

- Shortest anchoring depth - only 40/50 mm

- Quick assembly thanks to the short anchoring zone and the possibility of using a punch-tool in aerated concrete

- Specially-formulated nylon allows best performance installation for use in all base material categories according to ETAG 020 (A, B, C, D)

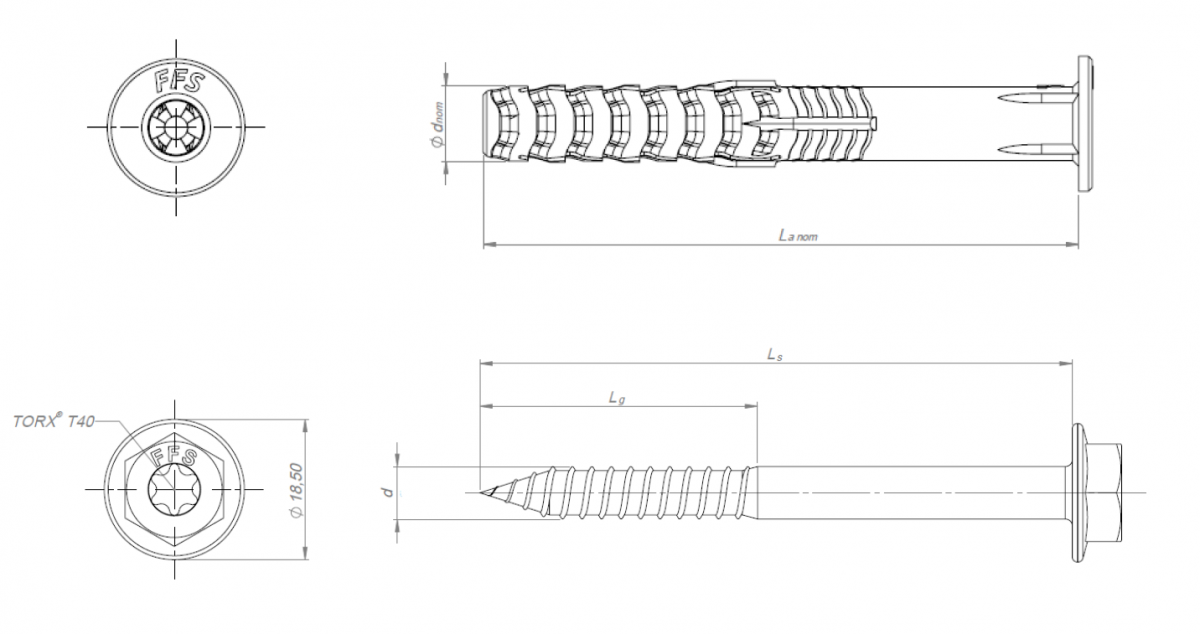

- Internal plug geometry designed to fit the screw head

- Plug design ensures multi-axis expansion

- Collared plug for fixing of hard materials (eg. steel)

Product information

Size |

Product Code |

Plug |

Screw |

Fixture |

Screw drive |

||

Diameter |

Length |

Diameter |

Length |

Hole diameter |

|||

d |

l |

d1 |

L1 |

df |

|||

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

- |

||

Ø10 |

R-FFS-N-10K050 |

10 |

50 |

7 |

59 |

12,5 |

T40 |

R-FFS-N-10K060 |

10 |

60 |

7 |

69 |

12,5 |

T40 |

|

R-FFS-N-10K080 |

10 |

80 |

7 |

89 |

12,5 |

T40 |

|

R-FFS-N-10K100 |

10 |

100 |

7 |

109 |

12,5 |

T40 |

|

R-FFS-N-10K120 |

10 |

120 |

7 |

129 |

12,5 |

T40 |

|

Base material

-

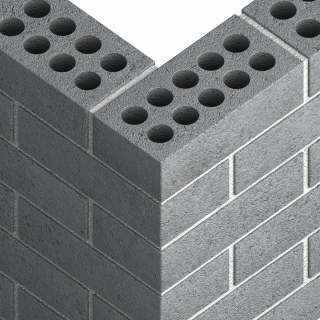

Concrete ≥ C12/15 (Use category A)

-

Solid Brick (Use category B)

-

Solid Sand-lime Brick (Use category B)

-

Hollow Brick (Use category C)

-

Hollow Sand-lime Brick (Use category C)

-

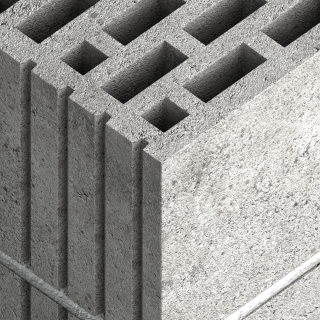

Hollow Lightweight Concrete Block (Use category D)

-

Aerated Concrete Block (Use category D)

-

Cracked concrete ≥ C12/15 (Use category A)

Applications

- Ventilated facades

- Door and window frames

- Garage doors

- Gates

- Industrial doors

- Facade (substructures made of wood and metal)

- Wall cabinets

- Satelite dishes

- Shelves

- Handrails

- Cable trays

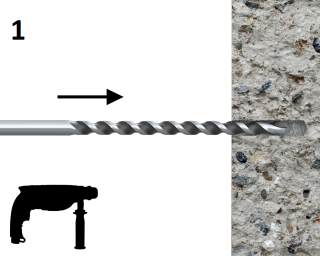

Installation guide

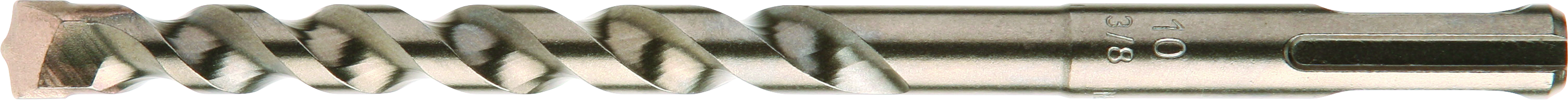

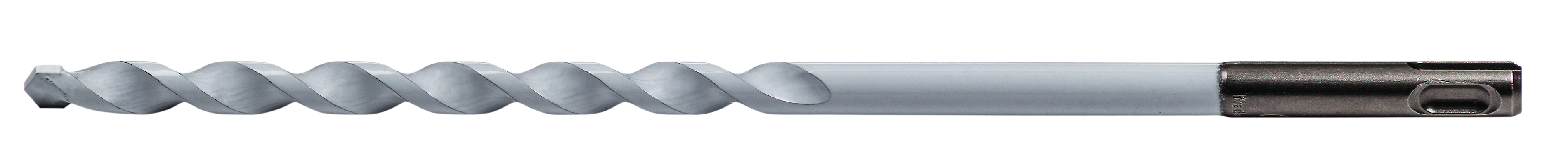

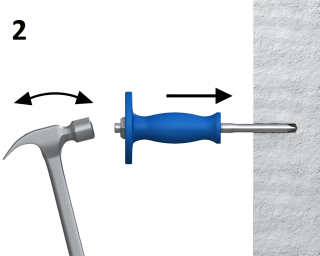

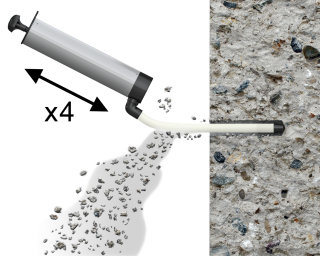

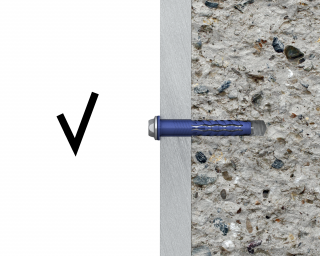

- Drill a hole of required diameter and depth (figure 1 - base material A,B,C,D) or use punch-tool in aerated concrete (figure 2 - base material D)

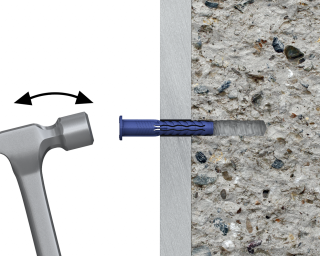

- With a hammer, lightly tap the plug through the fixture into hole until fixing depth is reached

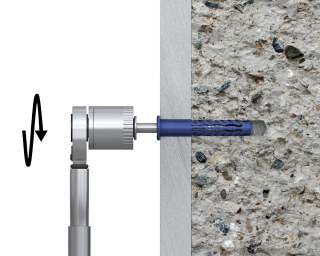

- Tighten the R-FFS screw

Installation data

Size |

Ø10 |

Ø10 |

||

Hole diameter in substrate |

d0 |

[mm] |

10 |

10 |

Min. hole depth in substrate |

h0 |

[mm] |

50 |

60 |

Min. installation depth |

hnom |

[mm] |

40 |

50 |

Min. substrate thickness |

hmin |

[mm] |

100 |

100 |

Min. spacing |

smin |

[mm] |

70 |

80 |

Min. edge distance |

cmin |

[mm] |

50 |

70 |

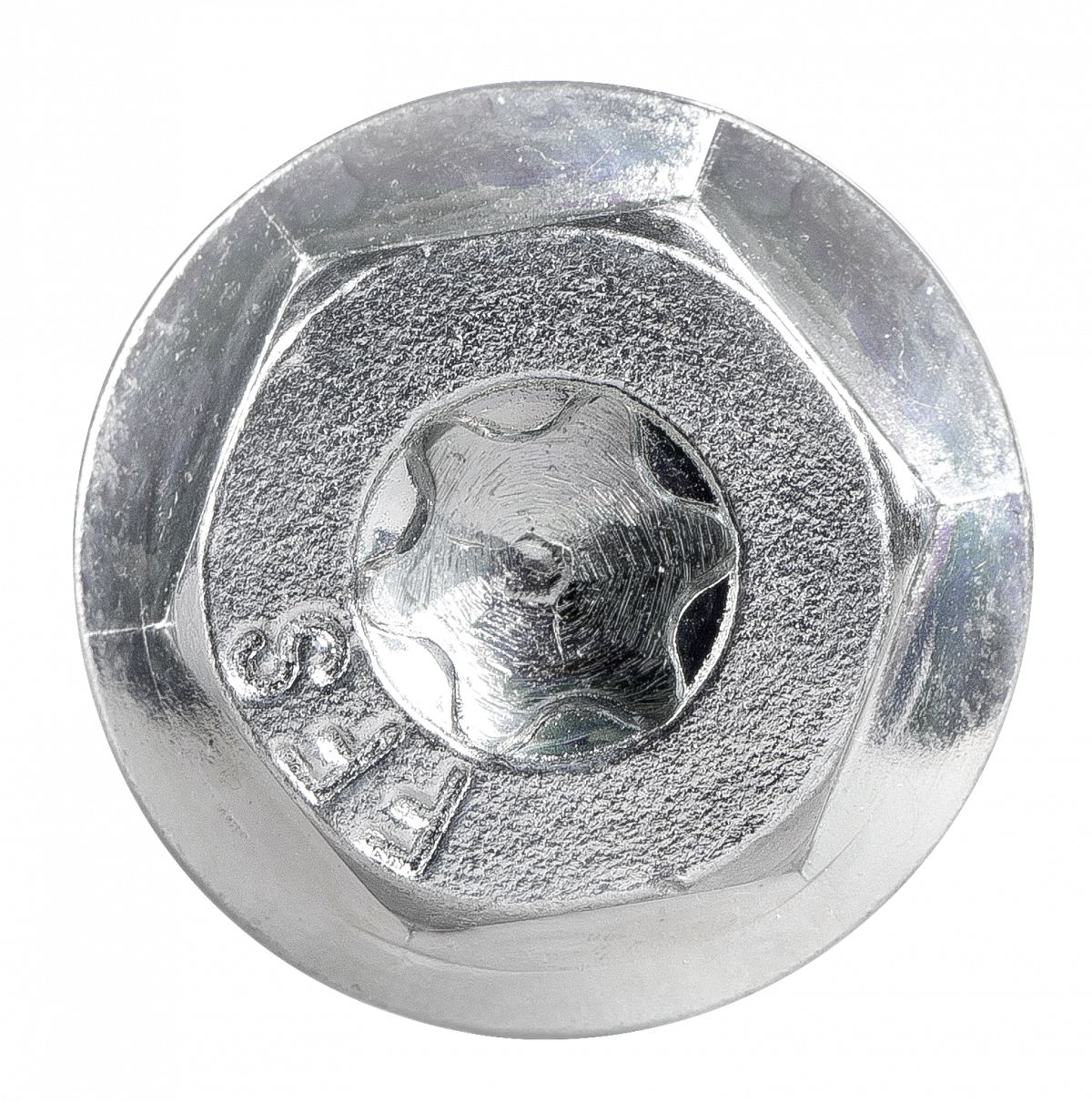

Head size |

sw |

[mm] |

13 |

13 |

Screw drive |

- |

[-] |

T40 |

T40 |

Effective embedment depth |

hef |

[mm] |

40 |

50 |